Extract from An Essay on Stereotype Printing by Thomas Hodgson, 1820.

Earl of Stanhope's Process Described

This process may be described nearly as follows: but it must be premised, that its success depends upon a number of minute details which can only be learnt by practice.

The types, with which the pages are composed, are the same in in every respect, as those in ordinary use, excepting that the shoulders, instead of being dressed off, are left square, as they come out of the mould. The spaces are also higher than usual, being equal in height to the shoulder of the types; the quadrats and leads are nearly as high as the spaces. As soon as a page is composed, it is imposed in a small chase, care being taken to surround it closely with pieces of brass or type-metal reglet, about the eighth of an inch thick, and equal in height to the quadrats. After a proof has been taken, and the page has been properly corrected, it is carried in its chase, and laid upon the moulding table, which is generally a polished and perfectly level plate of cast iron, about two feet long and fifteen inches broad. It is then planed, and care taken, that none of the spaces or quadrats are standing up. A frame of brass or bell-metal, about half an inch deep, is afterwards placed over it, so that the face of the page appears within the opening of the frame. Upon the depth or thickness of the frame depends the strength of the mould. The frame is raised upon four pins, or legs, screwed into its under surface, and which passing, partly on the outside,and partly on the inside of the chase, rest upon the table, and so support the frame quite level. The sides of the opening in the frame are not perpendicular, but sloped, or beveled of from the under to the upper side, at a considerable angle; this slope, however, does not rise from the extreme inner edge, but between this and the commencement of the slope there occurs a small flat ledge. —The inner edge of this ledge fits closely round the brass reglet surrounding the page; and the legs, upon which the frame rests, should be of such a height as to allow the ledge to sink a little below the upper surface of the brass reglet.— Upon the height of the legs and the consequent sinking of the ledge below the reglet, depends the thickness of the future plate. The use of te brass reglet is to form an edge all round the plate, below the shoulder of the letter , to allow of it being fastened to the blocks of wood upon which it is raised, when used for printing with.

When the page is thus disposed, the face of it and the inside of the frame are lightly oiled; it is then ready to receive the plaster of Paris, destined to form the mould. This must have previously been well baked, beat small, and finely sifted; but as this is a troublesome operation, it is generally bought ready prepared for use. A sufficient quantity of plaster is then carefully mixed in a proper vessel with water, to about the consistency of syrup; and a portion of this, sufficient to cover its face, is poured upon the page. This is then well worked for a short time with a small brush, in order to force it into the face of the types; and the remainder of the plaster is afterwards poured on, so as to fill all the opening in the frame. At the moment of its becoming fixed, a brass rule is slid over the frame, and by this means all the superfluous and uneven parts of the plaster are struck off; and the back of the mould rendered smooth and level.— When the mould has acquired the proper degree of firmness, it is removed from the page, by gently raising the frame from the chase. It requires considerable skill to be able to catch the precise moment of doing so; as should it be attempted too soon, the mould would be apt to break, or to be altered in its shape; and if too late, the kerned types could not be separated from the mould without injury. When the frame and mould are separated from the page, they are set aside for a short time to dry; and the mould, separated from the frame is carried to the drying oven, which contains a semi-circular rack, divided into numerous compartments, in one of which the mould is placed. Here it is baked, at the usual heat of ovens, until it assumes a slight brown colour, which is generally in about 3 or 4 hours.

|

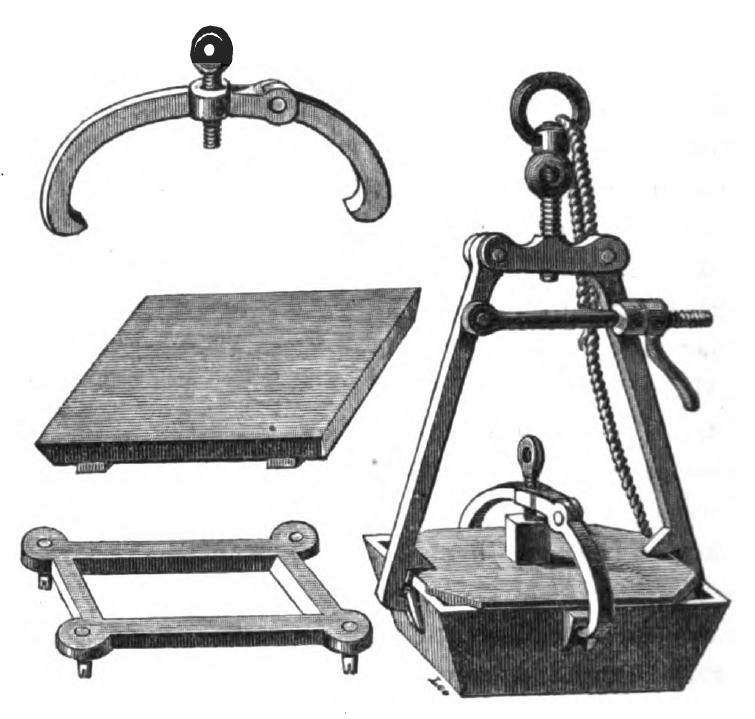

| Illustration from Typographia: an historical sketch of the origin and progress of the Art of Printing by Thomas Curson Hansard, which also describes Stanhope’s process. |

When the mould is taken from the oven, a small nick, called a gate, is cut at each of its four corners, to admit the melted metal, and it is then placed in the casting pan. This is an oblong square vessel of cast iron, about four inches deep; the sides of which slope outwards at a small angle. On the bottom of the pan rests a plate of iron, the upper surface of which is turned smooth and level, and the four comers rather rounded of to allow the melted metal to flow under it, to facilitate which the are also cut some grooves on its under side: upon this plate is placed the mould with its face downwards. Both the pan and the plate must have been previously heated in an oven to about the same degree of heat as the metal. The pan is covered with flat iron lid, the corners of which are rounded off to admit the metal and the pan is taken hold of by a pair of small clamps, the ends of which fix into cavities purposely made at its opposite sides. A long screw, in the centre of the clamps, acting upon a knob upon the cover of the pan, at the same time that it causes the clamps to take fast hold of the pan, keeps the cover firmly fixed in its place. The pan is then raised by a small crane, and lowered into a plumber’s melting pot, containing about three or four hundred weight of melted type-metal. It is lowered so far as to allow a small quantity of the metal to flow into the pan, through the openings left at each corner of the lid; it is then raised, and kept for some time half immersed in the metal, to allow the pan and mould to acquire the proper heat, and to effect the expulsion of the air out of the face of the mould. When this is thought to be effected, the pan is sunk lower, and the metal allowed to flow gently into it, till it is full; were it to rush in too quickly the mould would probably be broken. It is then sunk to the bottom of the melting pot, where it is allowed to remain about ten minutes. By this operation, the plate, lying on the bottom of the pan,is raised by the greater specific gravity of the melted metal, and pressing upwards against the mould, not only forces the metal into its face, but forms the stereotype plate, by cutting off the metal, contained within the cavity of the mould, from the surrounding metal, and by rendering the back of the plate as smooth and level as its own surface—The casting is by far the most difficult part of the process, and requires the greatest skill to execute well; many who have even received instructions in the art, never having been able to obtain a single perfect plate. The most essential points to insure success appear to be,—not to immerse the pan and its contents too suddenly,—and not to do so until they have acquired the same degree of heat as the melted metal and until all the air has been expelled. But the placing of the mould with its face downwards must always prove a radical defect in this process; as it seems almost impossible, that so situated, the air can ever be completely driven out of the face of the mould.

When the pan has lain a sufficient time in the pot it is raised out of it and swung round by crane over the cooler, which is a long shallow vessel, containing a small quantity of water, and some loose bricks, nearly immersed in the water. Upon one of these bricks the pan is set, and there it is left to cool. When it has cooled sufficiently, it is laid upon a block of wood, and the clamps unscrewed; the cover is removed, and the contents of the pan, which then present the appearance of a solid mass of type-metal, are turned out upon the block.—The workman then takes a wooden mallet, and with repeated hard blows strikes off the corners and edge of the upper side of this mass of metal.—When these are removed, the stereotype plate will be found lying near the top, between the mould and floating plate. As much of the mould, which is always destroyed by the process, as can be removed with the hand, is then separated from it, and the plate is soaked in water to soften the remainder, from which it is afterwards cleaned by picking, brushing, &c. The plate is then examined, to ascertain if it will answer, in which case the page, from which the mould was taken, is returned to the compositor; if it will not, another mould is taken from it, and the operation repeated.

When a good plate has been obtained, the roughness of the edges is removed with a plane, and the plate reduced to the proper size. A proof is next taken from it, and the several imperfections of the casting marked upon the margin. The plate is then delivered to the picker, who, with his picking instrument (generally a fragment of a fine gold-smith’s brooch, sharpened to a point, in the manner of a graver), opens out such letters as require it, or will admit of it, and clears away all superfluous pieces of metal. When a letter is so imperfect, as not to be capable of be being repaired with his picker, he strikes it out with a punch of the same size as the letter, or cuts it out with a graver; and turning the plate with its face upon the table, introduces s type of the proper kind into the opening made by the punch. He thrusts it down till it touches the table, and then saws off the portion of the shank of the type standing above the back of the plate; rubbing the place over, with any of his tools will sufficiently fix the introduced type. In this manner a whole word, or more, may be removed, and others inserted; but when the insertion is large, it must be soldered in. The picker also, with a square pointed graver, cuts down all the white lines, which would be in danger of marking when printing.

When used, the plates are raised upon blocks of wood or brass, furnished at the sides with small ledges, which overlap the edges of the plate, and being fastened down with screws hold the plate firmly fixed to the block. These blocks are imposed in a chase with furniture, regulated to suit the margin, in the same manner as ordinary pages. Alter being used, they are washed with ley, to clean them from the ink, and wrapped in a sheet of paper; they are generally laid by in a small box, divided in the middle by a partition, on one side of which are put the plates forming the inner form of the sheet, and on the other those of the outer form.

News

2023 December2018 April

2017 June

2016 July

2015 July

2015 June

2015 May

2015 February

2014 August

2014 July

2014 June

2014 May

2014 April

2014 March

2014 February

2014 January

2013 December

2013 November

2013 October

2013 September

2013 June

2013 May

2013 April

2013 February

2013 January

2012 December

2012 November

2012 October

2012 September

2012 July

2012 June

2012 May

2012 April

2012 March

2012 February

2011 December

2011 November

2011 October

2011 September

2011 August

2011 July

2011 June

2011 May

2011 April

2011 March

2011 February

2011 January

2010 December

2010 November

2010 September

|

Find us on

Google Maps

|